- Про ДДМА

- Путівник по ДДМА

- Статут

- Концепція розвитку

- Пантеон слави ДДМА

- Герої війни

- Ліцензія

- Ліцензування та акредитація

- Сертифікати

- Мова освітнього процесу

- Документи про вищу освіту

- Звіт ректора

- Вчена рада

- Освітні програми

- Навчальні плани

- Кошторис

- Фінансовий звіт

- Штатний розпис

- Штатний розклад

- Вакантні посади

- Загальна інформація

- Символіка

- Контакти

- Історія

- Матеріальна база

- Нормативні акти

- Публічна інформація

- Ректорат

- Факультети

- Підрозділи

- Абітурієнту

- Умови вступу

- Випускникам загальноосвітніх шкіл

- Випускникам коледжів, ВПУ, технікумів

- Вступ до магістратури

- Вступ до аспірантури

- Приймальна комісія

- Повторний вступ на бюджет та відшкодування вартості навчання

- Підготовчі курси

- Правила прийому до ДДМА у 2025 році

- Перелік спеціальностей

- Освітній центр «Донбас-Україна» і «Крим-Україна»

- Вступникам з Криму і Донбасу

- Вступникам, які знаходяться за кордоном

- Вступникам - ветеранам війни

- Практична підготовка школярів до здачі ЗНО з хімії. «ХІМІЧНІ СТУДІЇ»

- Студентський науковий гурток «Математичні студії»

- Заочне відділення

- Документи які необхідно подати при вступі на бюджет

- Наука

- Студенту

- Каталог дисциплін вільного вибору

- Атестація щодо вільного володіння державною мовою

- Центр розвитку кар’єри

- Стипендія

- Навчальні плани

- Табель-календар освітнього процесу на 2025-2026 навчальний рік

- Розклад дзвінків

- Розклад занять для денної форми навчання

- Розклад заліково-екзаменаційної сесії денної форми навчання

- Графік захисту кваліфікаційних робіт

- Розклад занять для заочної форми навчання

- Навчання на заочній формі навчанні

- Дуальне навчання

- Навчання за кордоном

- Кампанія "Відкрий Європу"

- Військова кафедра

- Правила поведінки здобувачів ДДМА

- Спорт

- Кодекс честі

- Працевлаштування

- Програма безперервної освіти

- Практика

- Випускнику

- Громадські організації

- Редакція

- Новини

ENG

Донбаська державна

Ученість — солодкий плід гіркого коріння.

Доклади серця свого до навчання і вуха свої до розумних слів

Вчись не для того, щоб знати більше, а для того, щоб знати краще.

Важлива не кількість знань, а якість їх.

Є тільки одне благо - знання й тільки одне зло - неуцтво.

Єдиний шлях, що веде до знання, - це діяльність.

Бич людини - це уявлюване знання.

Знання - сила.

Знання - знаряддя, а не ціль.

Запам'ятовувати вміє той, хто вміє бути уважним.

Донбаська державна

машинобудівна академія

Erasmus+ Bioart News

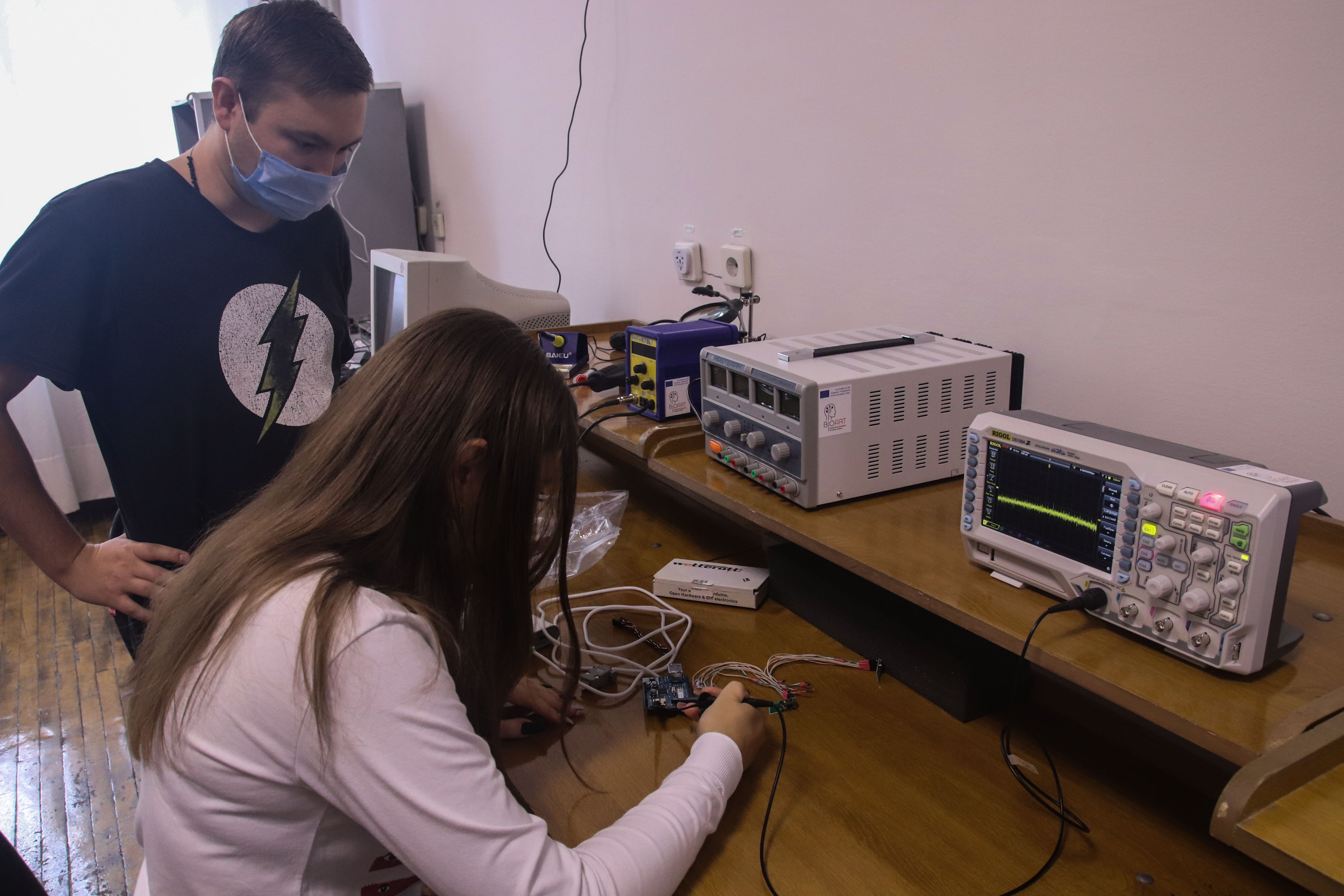

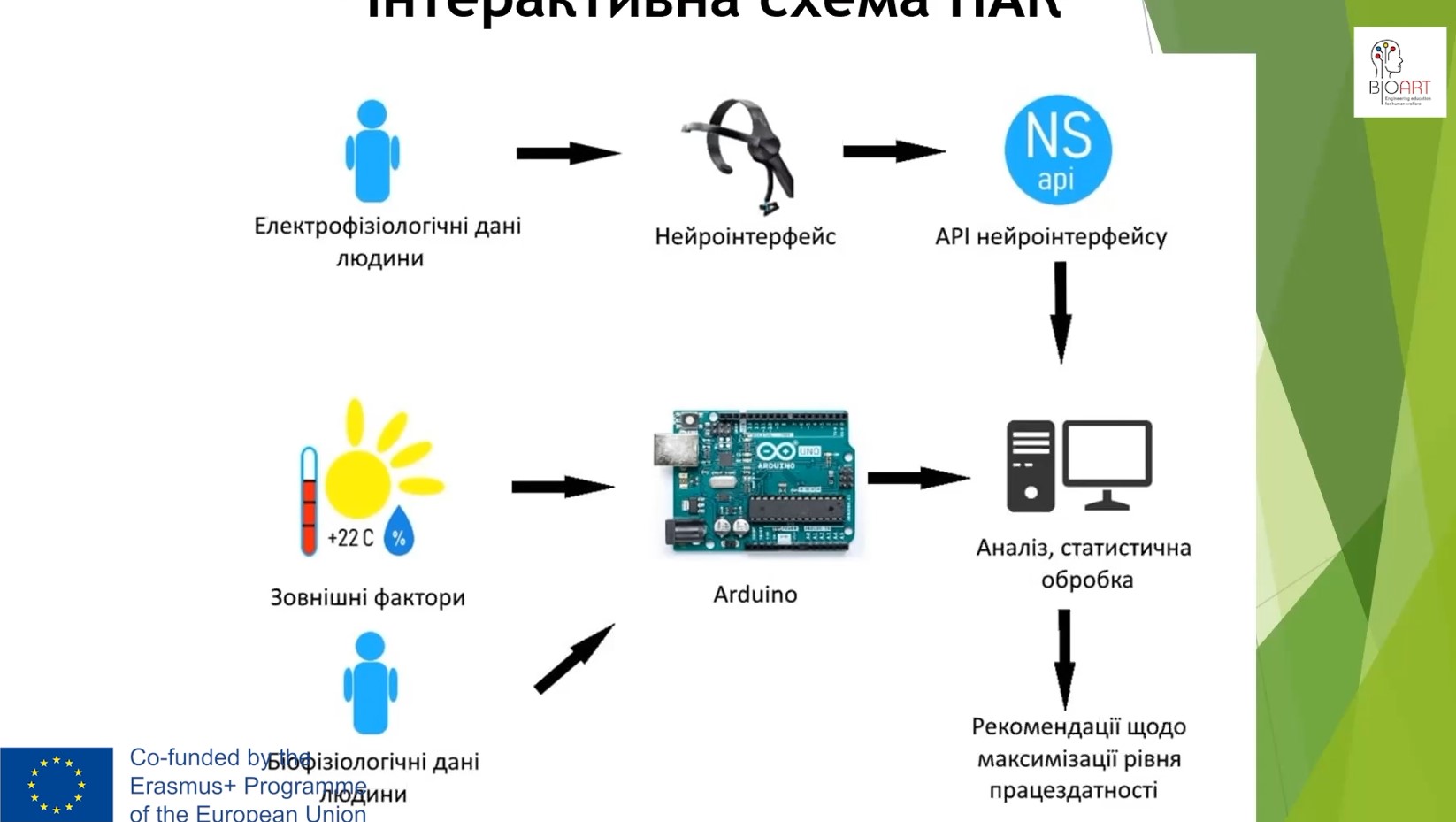

Provision of innovations in the educational process of the department of computer information technologies

The medical field of CIT began to develop in 2009, when the head of the Department of Computer Information Technology, Professor Tarasov A. F. returned from an internship at the British company Delcam, which developed software for creating implants and prostheses for humans.

In 2015, the department began cooperation with "Motor Sich", which produces endoprostheses of the hip and knee joints, with the Institute of Pathology of the Spine and Joints. In 2017, the department began work on the international project Erasmus + "BIOART". This allowed the creation of bioelectronics and biomechanics laboratories with equipment and software, and students and teachers - to undergo teacher training in partner countries. Example of laboratory equipment: signal generator and multi-channel oscilloscope, Raspberry Pi microcomputers, debug boards and sensor CITs, a 3D printer, a virtual reality helmet and a computer.

On this foundation, as part of the specialty "Computer Science" at the DSEA, a new educational program "Computer Science in Medicine" was created to prepare students in the use of information technology in the medical field.

The availability of modern equipment helps to better teach students, including the completion of theses. Student research works are performed at a decent level and are successfully defended at international competitions.

In November, the DSEA signed a memorandum with the public association IT-Cluster Donbass, which will help implement large joint projects in the IT-field. The educational process of the department will receive modern IT-innovations from this cooperation. Teachers of the department, in turn, plan to hold webinars, conferences, competitions, etc. for everyone. This will ensure the development of the intellectual potential of Kramatorsk.

ON-LINE MONITORING OF THE BIOART PROJECT BY ERASMUS + OFFICE EXPERTS UKRAINE

On November 27, an online monitoring of the BIOART project was conducted. The use of the online format allowed to attract representatives of all partner universities. The meeting was opened by the Rector of the National University "Zaporizhzhya Polytechnic", Ph.D. prof. Belikov Serhiy Borysovych, Rector of Vinnytsia National Technical University, Ph.D. prof. Grabko Volodymyr Vitaliyovych, Rector, Donbas State Engineering Academy, Ph.D. prof. Kovalev Viktor Dmitrievich and Vice-Rector for Scientific and Pedagogical Work of the Azov State Technical University, Ph.D. prof. Cheilyakh Alexander Petrovich. A significant impact of the BIOART project on the development of university capacity was noted. Project coordinator prof. David Luengo reported on the current state and results, noted the effective work of the teams involved partner universities.

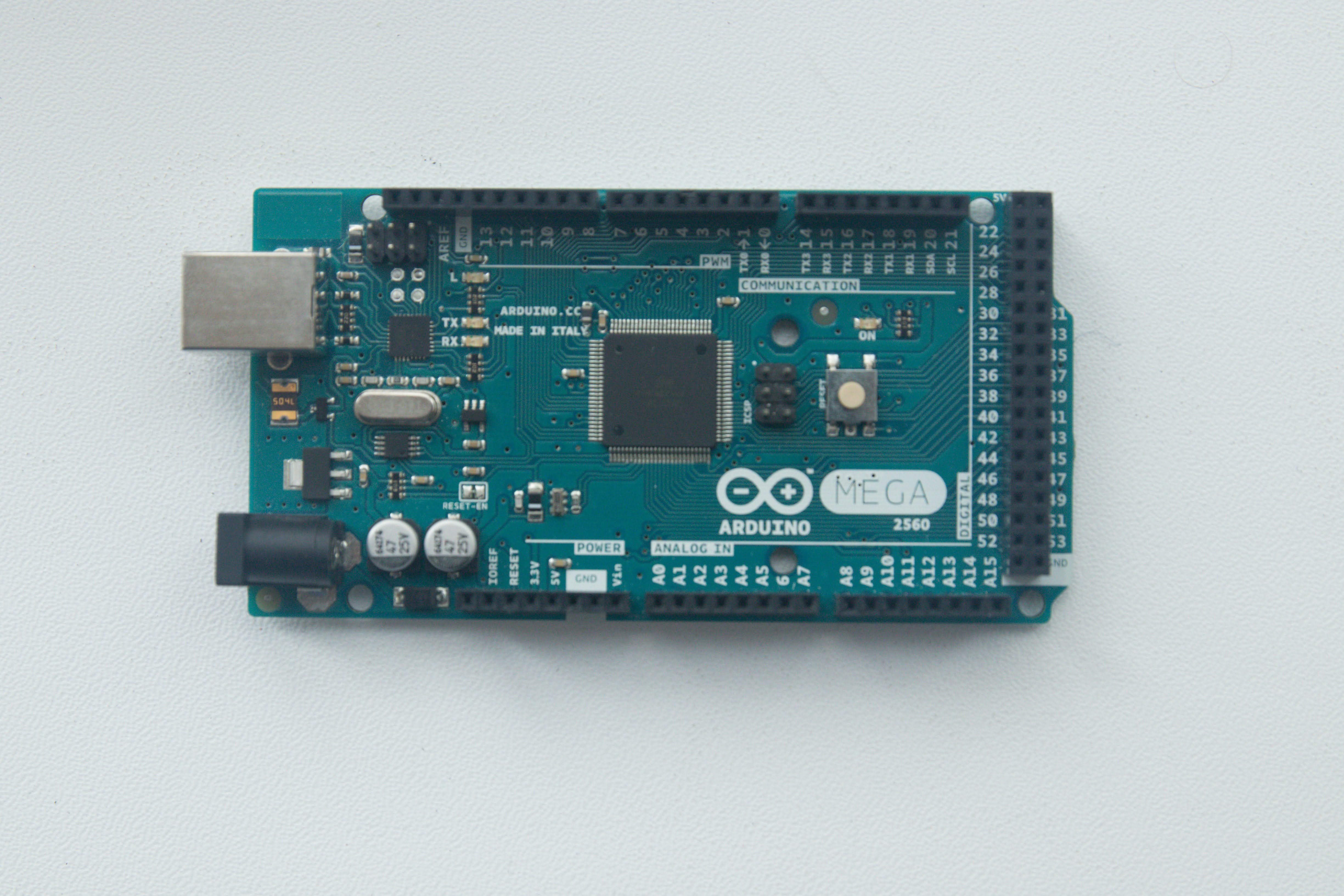

The Laboratory of Bioelectronics was opened at the Academy

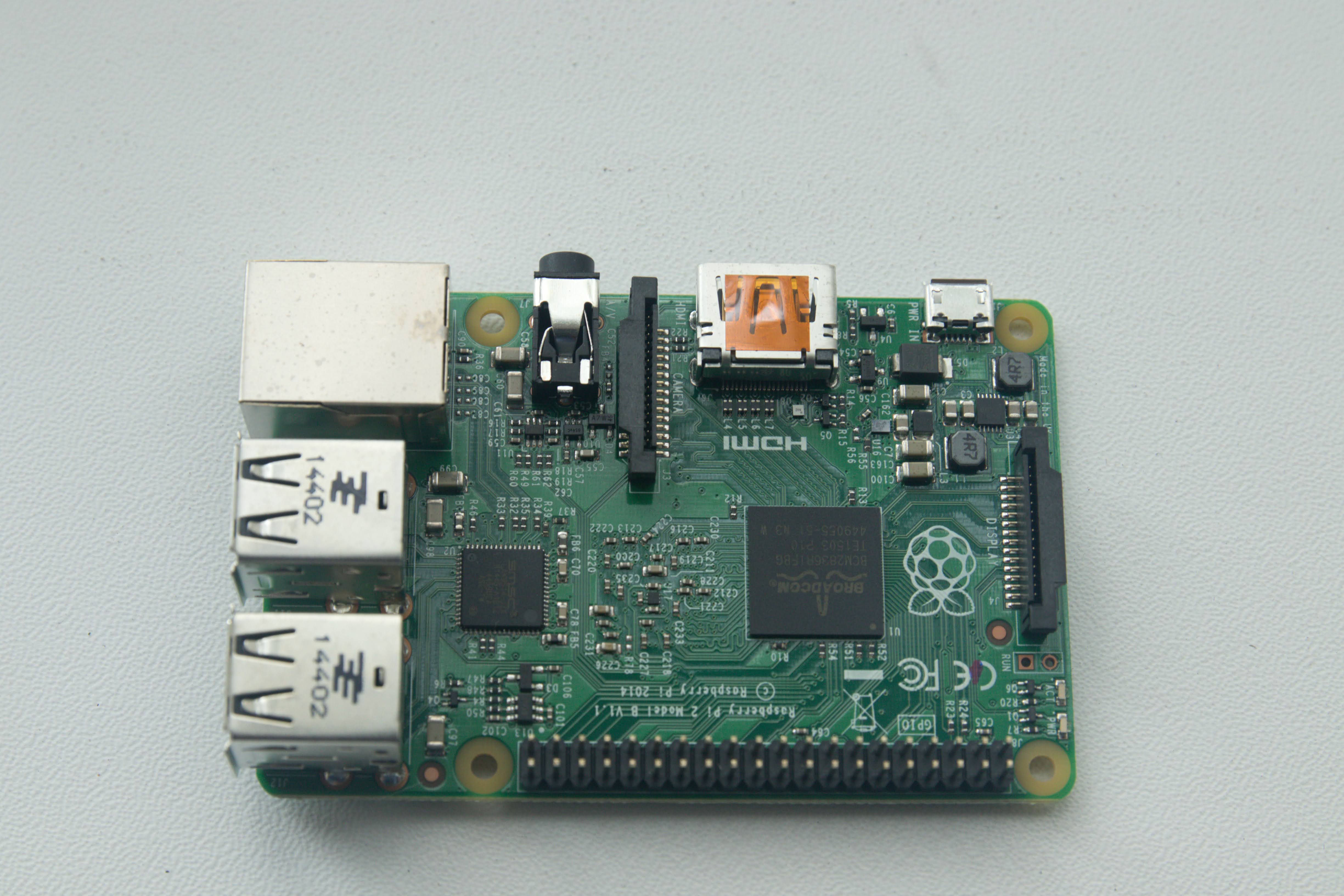

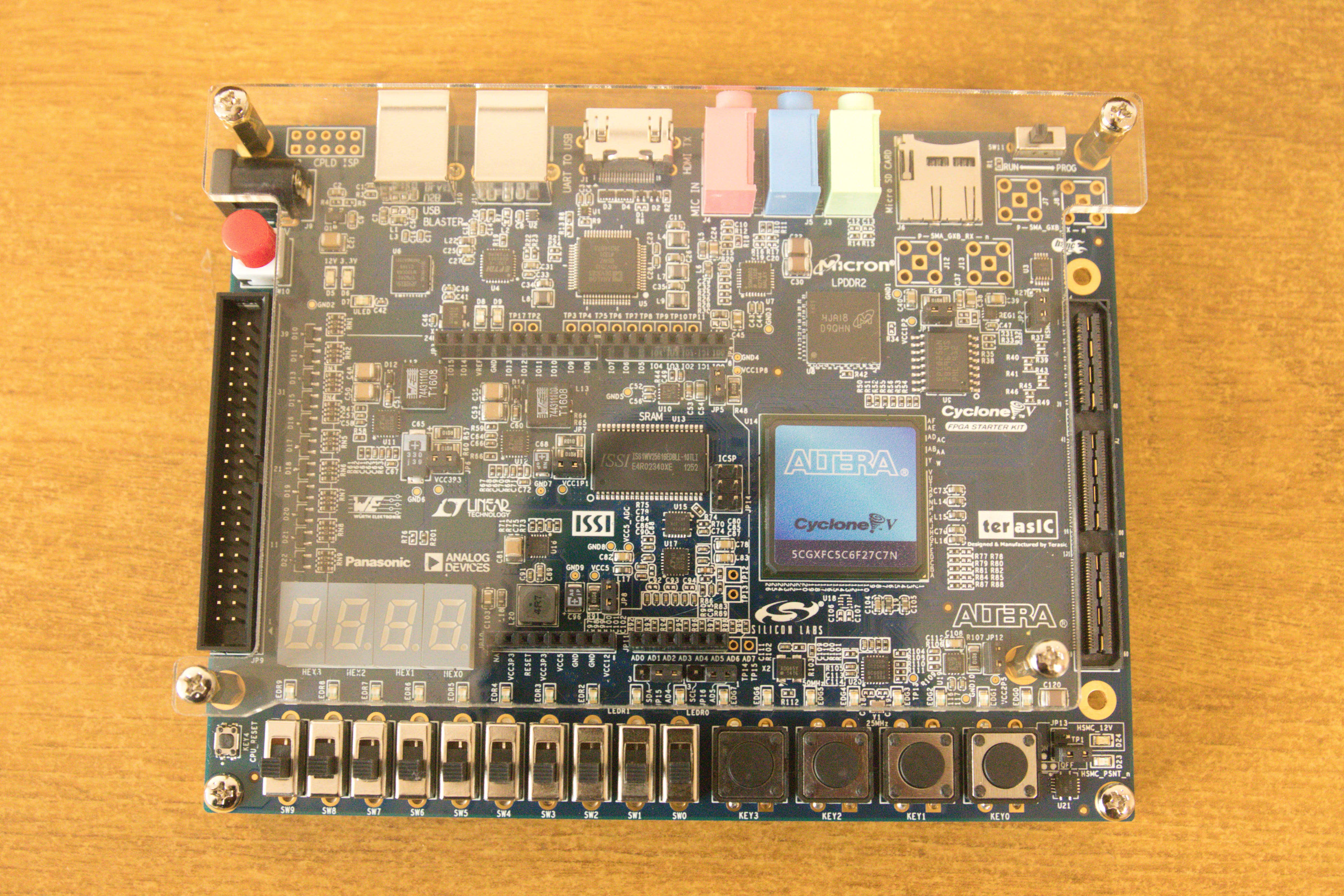

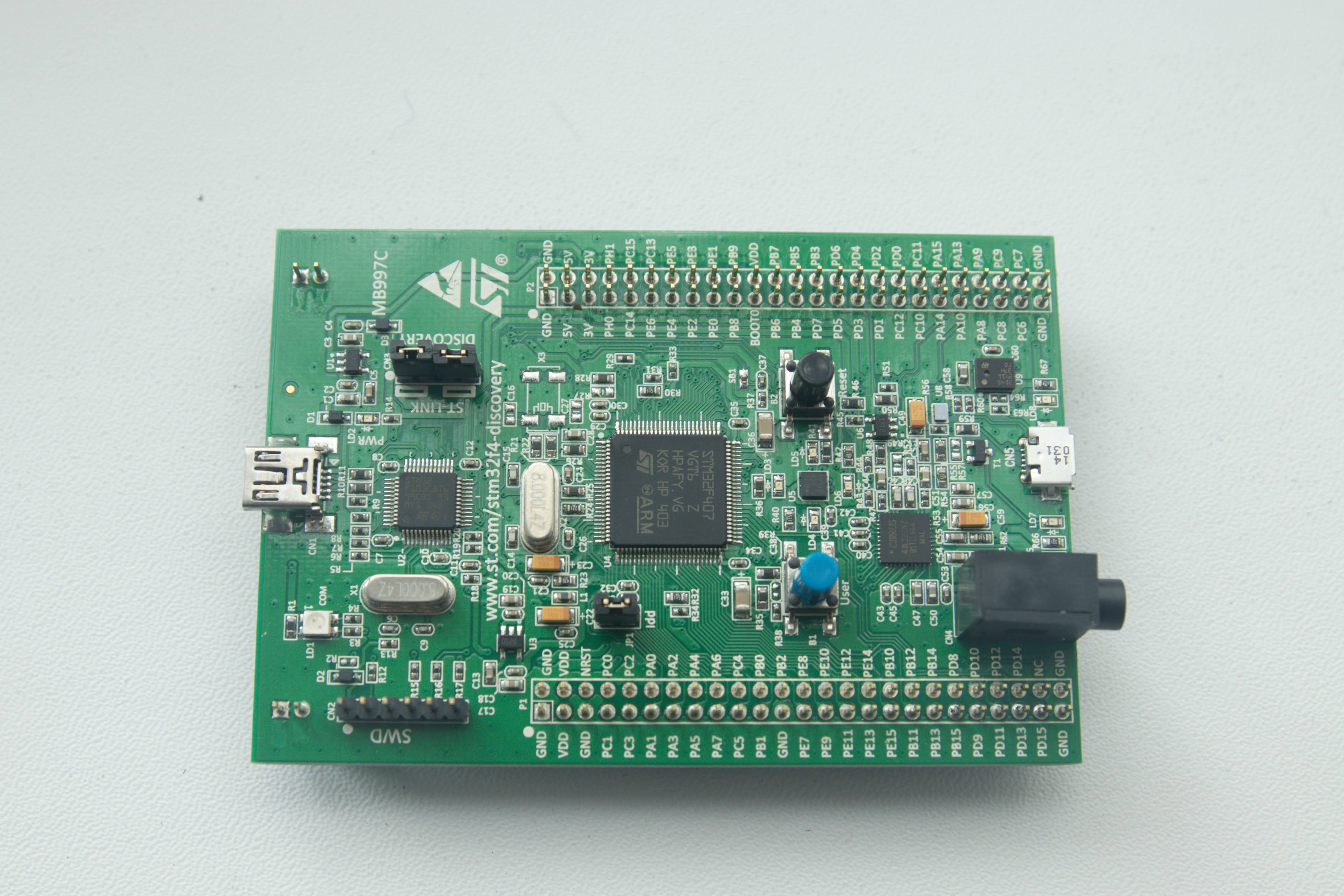

At the beginning of the academic year, a bioelectronics laboratory began its work at the DSEA on the basis of the Department of Computer Information Technologies. The creation of the laboratory became possible due to the participation of the department staff in the BioArt Erasmus + project. Students were able to use modern equipment in the process of studying various disciplines: signal generator, multi-channel oscilloscope, various debug boards based on Arduino, RaspberryPi, STM32, FPGA platforms for laboratory work, course and diploma projects. The presence of Raspberry Pi microcomputers, debugging boards based on the Arduino platform, STM32, FPGA, sensor kits, including medical, allow future professionals to develop prototypes of devices for the "Internet of Things", gain skills in working with medical sensors, collect miniature computing clusters, ie to fully immerse yourself in the world of modern software and hardware solutions.

Laboratory work on studying the signals of the SPI interface Arduino platform

RaspberryPi microcomputer

Board for learning FPGA technology

Board for studying STM32 architecture microcontrollers

Board for learning the Arduino platform

XLII SCIENTIFIC AND TECHNICAL CONFERENCE OF SCIENTIFIC AND PEDAGOGICAL WORKERS, DOCTORAL STUDENTS, GRADUATE STUDENTS, MASTER'S DEGREE CANDIDATES AND STUDENTS

The COVID-19 pandemic has made significant adjustments to its annual action plans. Thus, the annual scientific and technical conference of scientific and pedagogical workers, doctoral students, graduate students, master’s degree candidates and students was held remotely in November instead of April.

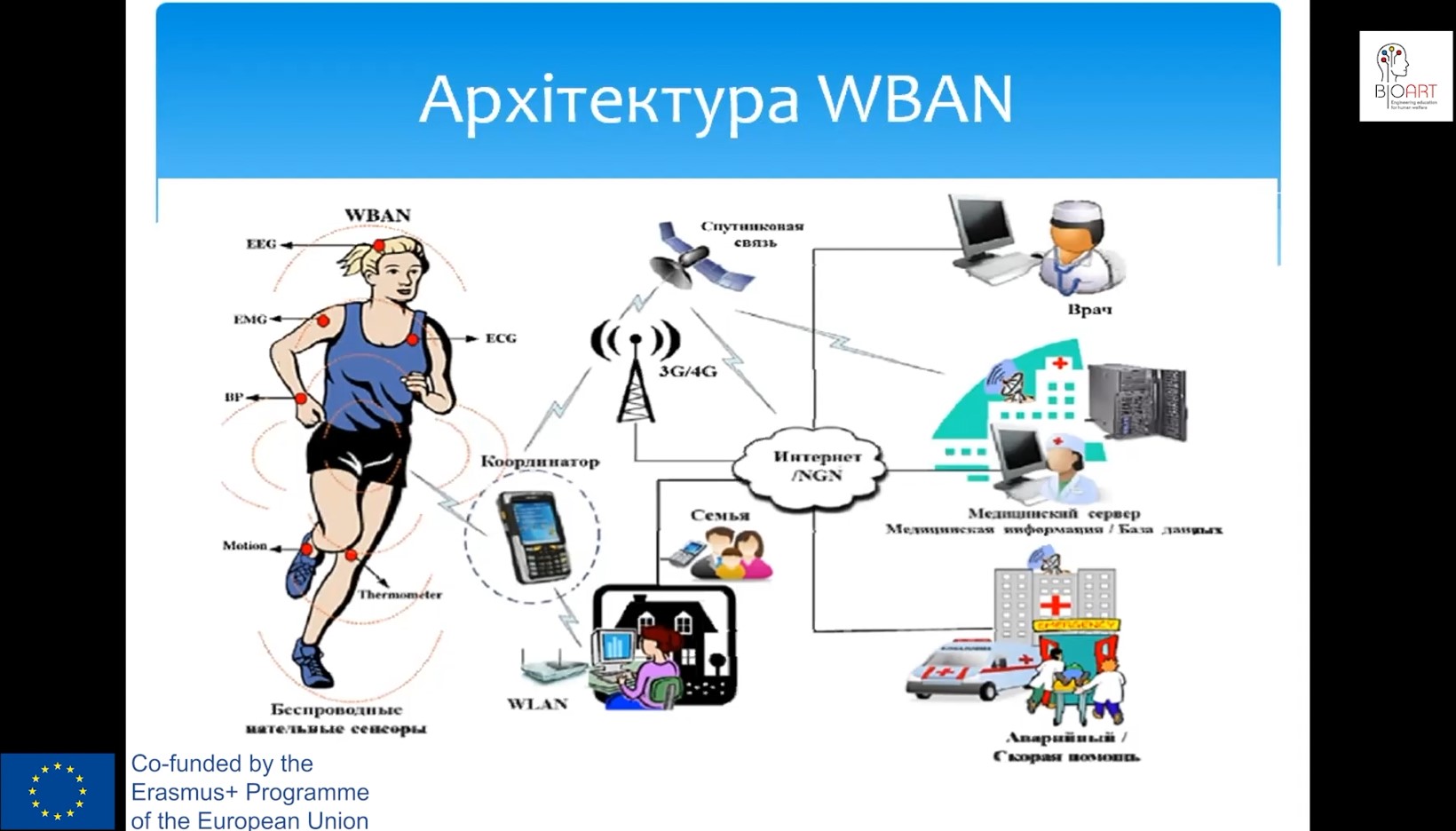

The subsection of computer information technologies was held on November 24. It was attended by 14 research and teaching staff, 2 graduate students, 25 undergraduates and 2 students. 39 reports were heard, 26 of them were student and 14 were made within the BIOART Erasmus + project. The list of reports can be viewed at the link.

Following the conference, the best reports were noted: young scientists - "Development of a software model of the control unit of LPM" Kovalenko AK, students - "Research of models, methods and information technologies of statistical analysis of external factors on human performance" Marchuk O.O. and Davidov Ya. S. gr. КН-19-1мн.

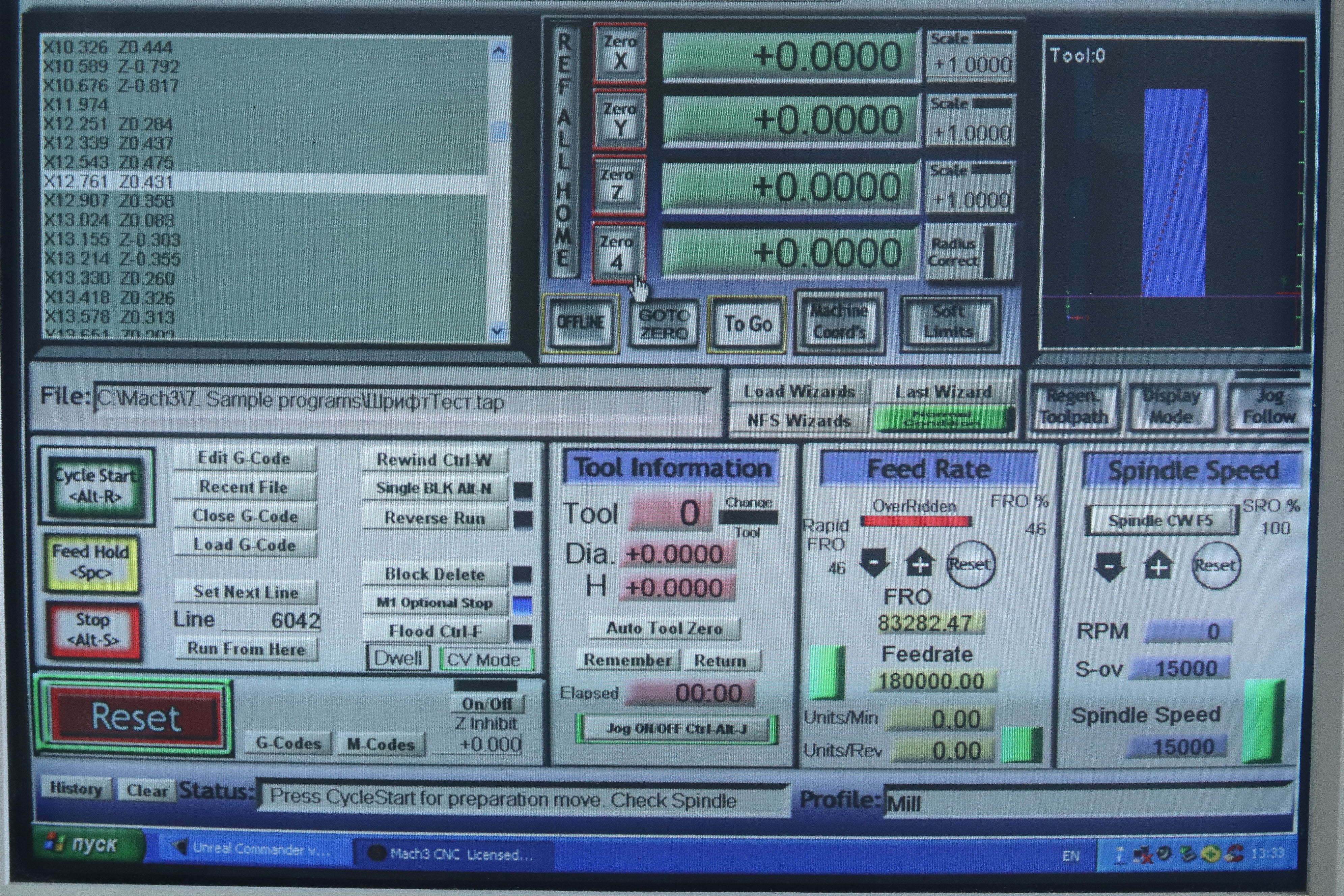

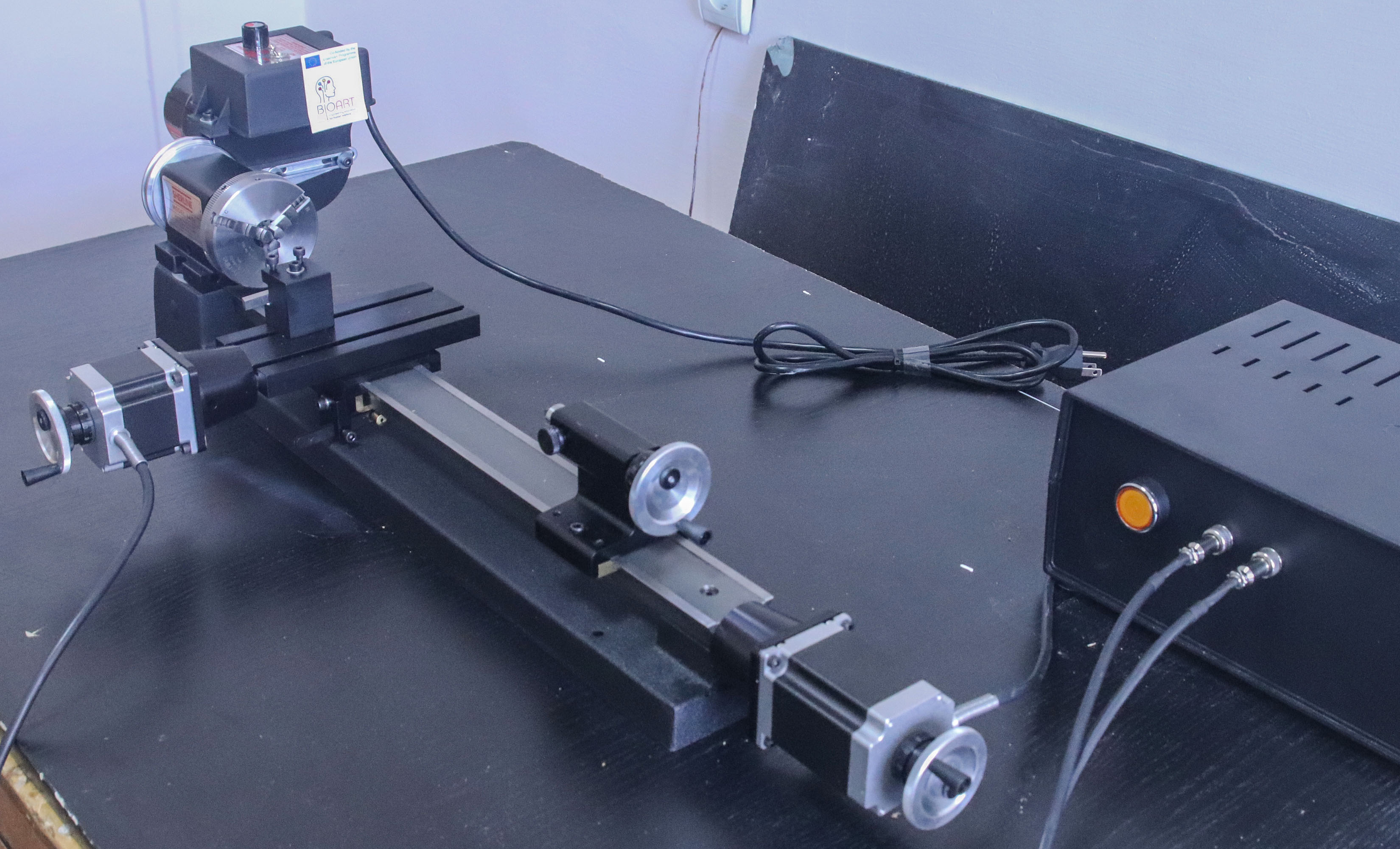

New CNC equipment in the biomechanics laboratory

Among the equipment that the department received in the framework of the BioArt Erasmas + project, there are machines on which you can make parts of complex configuration from hard plastics and metals. These are the Sherline 5410 CNC drilling and milling machine and the Sherline 4410 CNC lathe. Sherline is located in the United States and is widely known in the world for quality small machines. These machines allow you to perform machining of parts in both software and manual control mode.

The free version of Mach 3 is used as software for controlling motor controllers. It is enough to control the processing of medium-sized parts.

The Sherline 5410 CNC drilling and milling machine has a motor power of 0.6 kW, a spindle speed range of 70 - 2800 rpm, axial movement: X/Y/Z - 220/127/159 mm, respectively. Stepper motors to control the movement of the axes with a capacity of 0.2 kW.

The basic complete set allows to operate the machine at the same time control of movement of a desktop at once on three coordinates. The available version has a fourth axis of CNC on the basis of a rotary table, with a stepper motor. Thus processing of difficult surfaces by end mills is possible.

The Sherline 4410 CNC lathe has a motor power of 0.6 kW, spindle speed range 70 - 2800 rpm, spindle bore diameter 10 mm, rear headstock quill stroke 45 mm, rear headstock quill cone - MK1, turning diameter over frame 180 mm, turning diameter above the transverse caliper 90 mm, the distance between the centers 430 mm, the course of the transverse caliper 110 mm. Stepper motors to control the movement of the axes with a capacity of 0.2 kW. There is a complete set of equipment that allows you to process not completely cylindrical parts and cut threads.

The machine allows to carry out processing with simultaneous movement of the tool on two coordinates.

These machines perform such tasks as studying the principles of software coding for CNC systems, gaining skills in developing control programs for control systems for lathes and milling and drilling machines in the classical configuration, as well as with additional coordinates.

Also, machines can serve as a laboratory base for the creation of control systems, as well as analysis of the effectiveness of existing CAM systems. It is planned to use these machines in laboratory work on the manufacture of medical devices, including implants.

Більше статей...

- Virtual reality technologies are used in the educational process

- The Academy hosted a webinar on the use of CAE-systems for the training of medical professionals under the ERASMUS + "BOIART" program

- SKYPE-CONFERENCE OF ERASMUS + BIOART PROJECT IN UKRAINE

- PROBLEMS OF HIGHER EDUCATION IN THE COVID-19 AGE AND IN THE FUTURE